Conveying equipment Desin Maunual

Conveyor bottom

The bottom surface and conveying direction of the conveyor are the primary conditions for determining the selection of the conveyor. Therefore, we should first investigate the bottom surface and conveying direction of the conveyor. In addition, pay attention to the conveying direction when shunting and merging.

|

Bottom state of conveyor

|

|

|

|

|

Bag like soft bottom

|

||||||

|

Conveyor side status

|

|

|

|

|

Bag like soft bottom

|

||||||

|

Running direction and suitable model

|

Direction

|

→

|

↑

|

→

|

↑

|

→

|

↑

|

→

|

↑

|

→

|

↑

|

|

Type of machine

|

Belt conveyor

Chain machine Plate machine |

Belt conveyor

Chain machine Plate machine |

Belt conveyor

Chain machine Plate machine |

Belt conveyor

Chain machine Plate machine |

Belt conveyor

Chain machine Plate machine |

Belt conveyor

Chain machine Plate machine |

Belt conveyor

Chain machine Plate machine |

Belt conveyor

Chain machine Plate machine |

Belt conveyor

Plate machine |

Belt conveyor

Plate machine |

|

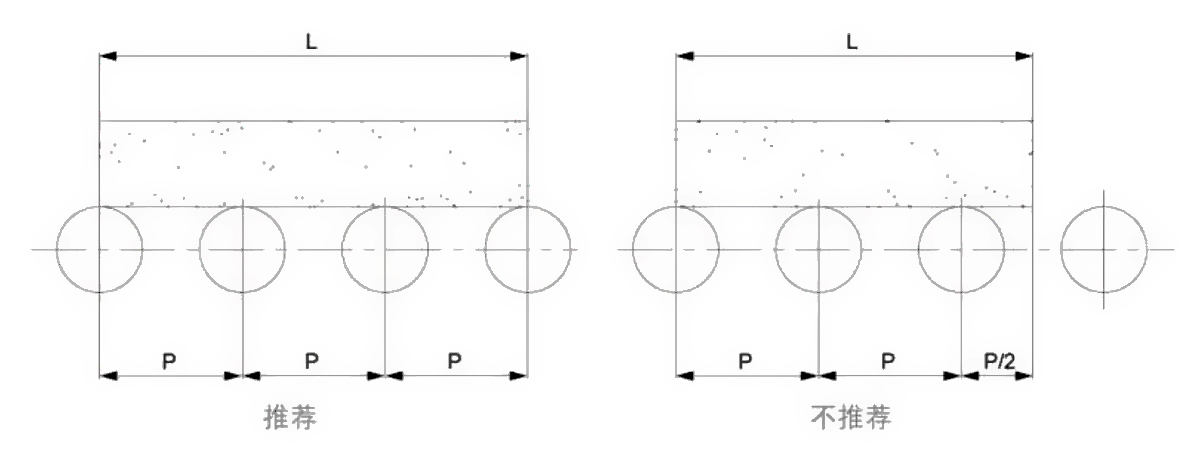

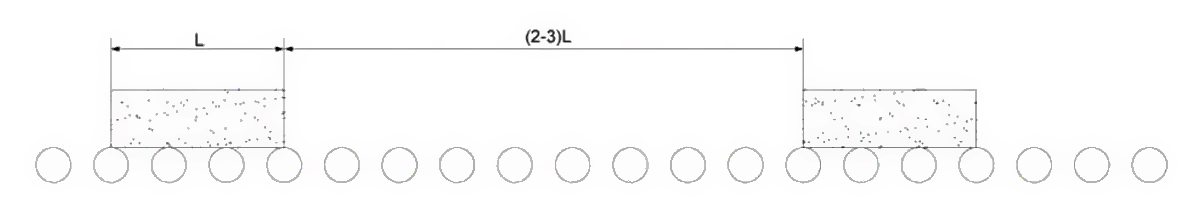

The distance between the conveying bottom and the roller (the conveying material is uniform, and the center of gravity of the conveying material is in the center) the conveying length of the conveying material (L) ≥ 3 × Roller spacing (P)

Conveying speed

Conveyor interval = (2-3) times the length of conveyor direction (L)

Conveying speed = (3-4) times the length of conveying direction x the number of conveyances per minute

Example: delivery per minute: 10

Length of conveying direction: 500mm

Conveyor interval: 2 times the length of conveyor direction (L)

Conveying speed =3x500x10/1000=15m/min